مواقعنا

الصور وأدوات التصميم

أفكار التصميم

- 2026 Hotel Bathroom Design Trends

- 2026 Hotel Lobby Design Trends

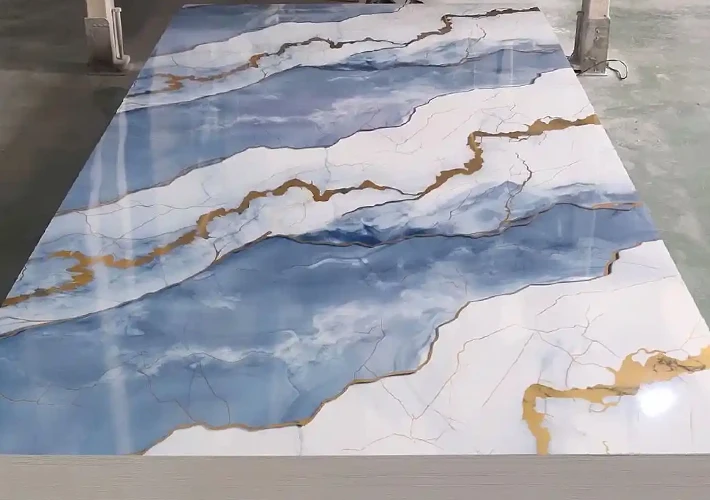

- 2026 UV Marble Sheet Design Trend

- Bamboo Charcoal Wood Veneer Marble Wall Panels for Public Spaces

- Hotel Holistic Customization for New Build and Renovation Projects

- Hotel Bathroom Renovation Trends in 2026

- A Complete Guide to Future-Ready Hotel Design and Investment

- WPC Wall Panels’ Most Popular Patterns in the UK

الغرف والمساحات

- How Acoustic Panels Improve Sound Quality in Hotels

- Why Are More and More Renovation Projects Starting to Use Bamboo Charcoal Wood Veneer?

- Why Are More and More Hotels in the US and Europe Choosing SPC Wall Panels for Bathrooms?

- How to Choose the Right Bed for a Hotel?

- Popular Colors and Applications for Acoustic Panels

- Wooden, Metal or MDF? Best Materials for Hotel Bedside Tables

- Best Hotel Room Furniture Suppliers for 3–5 Star Hotels

- What Are the Advantages of Acoustic Panels for Office Use?

كيفية التثبيت

- How to Install Bamboo Charcoal Wood Veneer

- هل يجب أن تكون الألواح الصوتية على الجدران أو الأسقف؟

- دليل خطوة بخطوة لتركيب ألواح الرخام المصنوعة من مادة البولي فينيل كلوريد

- طريقة تركيب لوحة الحائط WPC

- كيفية تركيب لوحات الحائط SPC؟

- كيفية تركيب قشرة الخشب الفحم الخيزران؟

- تحسين جودة الصوت باستخدام الألواح الصوتية

- كيفية تركيب قشرة الخشب الفحمي الخيزران؟

الغرف والمساحات

- PVC Marble Sheet Manufacturer in China for Hotel Interior Wall Projects

- Key Installation Points of WPC Wall Panel Concealed Door Systems

- Customization and Wholesale Services of PVC Marble Sheets Suitable for Star-Rated Hotel Decoration

- أنماط تصميم غرف النوم الداخلية: تعزيز الجماليات باستخدام الألواح الجدارية الحديثة

- هل يمكنني استخدام لوحات الحائط SPC في الحمام؟

- دليل أنواع ألواح الجدران

نصائح الخبراء المتميزين

- How to Shorten Hotel Guestroom Renovation Time by 30%?

- What Real Problems Will a Project Face If CE Documentation Is Incomplete?

- Bamboo Charcoal Wood Veneer Price Guide & Global Market Trends

- Top WPC Wall Panel Manufacturer and Factory for Global Projects

- Top 10 Best Acoustic Panels for Modern Interior Decoration

- How to Choose the Best Hotel Luxury Sofa for Your Project

- Latest Market Trends of WPC Wall Panels in 2025

- Common Sizes of Acoustic Wood Paneling: A Comprehensive Guide for Global Buyers

تعلم الأساسيات

- WPC Wall Panel Price in USA – Import Cost Guide

- Advantages of Using Soundproof Doors in Hotels

- Common Sizes of Acoustic Wall Panels in Ireland

- Fire Rated PVC Marble Sheet Price and Certification Cost Impact

- What are the benefits of bamboo charcoal panels?

- How to Choose the Right Acoustic Insulation Wall Panels for Commercial Projects

- Benefits of Using Acoustic Panels on Ceiling in Hotels

- How to Choose the Right WPC Wall Panel Supplier in China for Your Business

المجموعات الشعبية

إلهام

المجموعات الشعبية

إلهام

المجموعات الشعبية

إلهام

المجموعات الشعبية

إلهام

التثبيت والنصائح

المجموعات الشعبية

إلهام

التثبيت والنصائح

استكشفنا

التثبيت والنصائح