مواقعنا

الصور وأدوات التصميم

أفكار التصميم

- 2026 Hotel Bathroom Design Trends

- 2026 Hotel Lobby Design Trends

- 2026 UV Marble Sheet Design Trend

- Bamboo Charcoal Wood Veneer Marble Wall Panels for Public Spaces

- Hotel Holistic Customization for New Build and Renovation Projects

- Hotel Bathroom Renovation Trends in 2026

- A Complete Guide to Future-Ready Hotel Design and Investment

- WPC Wall Panels’ Most Popular Patterns in the UK

الغرف والمساحات

- How Acoustic Panels Improve Sound Quality in Hotels

- Why Are More and More Renovation Projects Starting to Use Bamboo Charcoal Wood Veneer?

- Why Are More and More Hotels in the US and Europe Choosing SPC Wall Panels for Bathrooms?

- How to Choose the Right Bed for a Hotel?

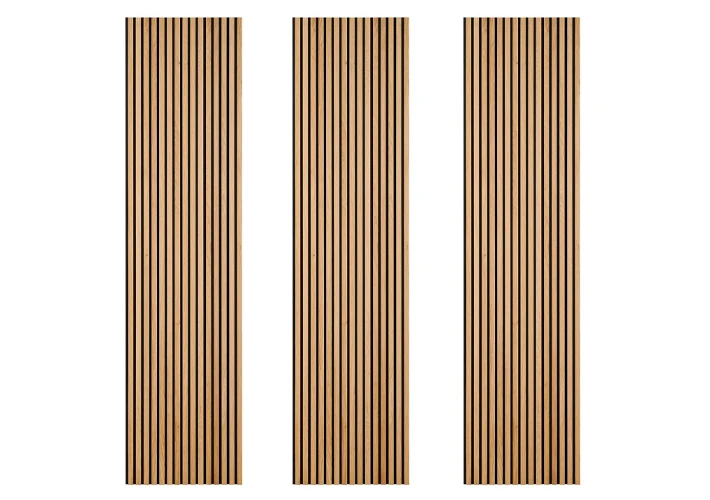

- Popular Colors and Applications for Acoustic Panels

- Wooden, Metal or MDF? Best Materials for Hotel Bedside Tables

- Best Hotel Room Furniture Suppliers for 3–5 Star Hotels

- What Are the Advantages of Acoustic Panels for Office Use?

كيفية التثبيت

- How to Install Bamboo Charcoal Wood Veneer

- هل يجب أن تكون الألواح الصوتية على الجدران أو الأسقف؟

- دليل خطوة بخطوة لتركيب ألواح الرخام المصنوعة من مادة البولي فينيل كلوريد

- طريقة تركيب لوحة الحائط WPC

- كيفية تركيب لوحات الحائط SPC؟

- كيفية تركيب قشرة الخشب الفحم الخيزران؟

- تحسين جودة الصوت باستخدام الألواح الصوتية

- كيفية تركيب قشرة الخشب الفحمي الخيزران؟

الغرف والمساحات

- PVC Marble Sheet Manufacturer in China for Hotel Interior Wall Projects

- Key Installation Points of WPC Wall Panel Concealed Door Systems

- Customization and Wholesale Services of PVC Marble Sheets Suitable for Star-Rated Hotel Decoration

- أنماط تصميم غرف النوم الداخلية: تعزيز الجماليات باستخدام الألواح الجدارية الحديثة

- هل يمكنني استخدام لوحات الحائط SPC في الحمام؟

- دليل أنواع ألواح الجدران

نصائح الخبراء المتميزين

- How to Shorten Hotel Guestroom Renovation Time by 30%?

- What Real Problems Will a Project Face If CE Documentation Is Incomplete?

- Bamboo Charcoal Wood Veneer Price Guide & Global Market Trends

- Top WPC Wall Panel Manufacturer and Factory for Global Projects

- Top 10 Best Acoustic Panels for Modern Interior Decoration

- How to Choose the Best Hotel Luxury Sofa for Your Project

- Latest Market Trends of WPC Wall Panels in 2025

- Common Sizes of Acoustic Wood Paneling: A Comprehensive Guide for Global Buyers

تعلم الأساسيات

- Fire Rated PVC Marble Sheet Price and Certification Cost Impact

- What are the benefits of bamboo charcoal panels?

- How to Choose the Right Acoustic Insulation Wall Panels for Commercial Projects

- Benefits of Using Acoustic Panels on Ceiling in Hotels

- How to Choose the Right WPC Wall Panel Supplier in China for Your Business

- What Are the Advantages of Oak Acoustic Panels?

- Common HS Codes Used for WPC Wall Panels

- Why Malaysian Buyers Source Acoustic Panels from China

المجموعات الشعبية

إلهام

المجموعات الشعبية

إلهام

المجموعات الشعبية

إلهام

المجموعات الشعبية

إلهام

التثبيت والنصائح

المجموعات الشعبية

إلهام

التثبيت والنصائح

استكشفنا

التثبيت والنصائح