Our Sites

PHOTOS & DESIGN TOOLS

DESIGN IDEAS

- What Do FF&E and OS&E Mean in the Context of Hotels?

- 2026 Hotel Bathroom Design Trends

- 2026 Hotel Lobby Design Trends

- 2026 UV Marble Sheet Design Trend

- Bamboo Charcoal Wood Veneer Marble Wall Panels for Public Spaces

- Hotel Holistic Customization for New Build and Renovation Projects

- Hotel Bathroom Renovation Trends in 2026

- A Complete Guide to Future-Ready Hotel Design and Investment

ROOMS & SPACES

- How Acoustic Panels Improve Sound Quality in Hotels

- Why Are More and More Renovation Projects Starting to Use Bamboo Charcoal Wood Veneer?

- Why Are More and More Hotels in the US and Europe Choosing SPC Wall Panels for Bathrooms?

- How to Choose the Right Bed for a Hotel?

- Popular Colors and Applications for Acoustic Panels

- Wooden, Metal or MDF? Best Materials for Hotel Bedside Tables

- Best Hotel Room Furniture Suppliers for 3–5 Star Hotels

- What Are the Advantages of Acoustic Panels for Office Use?

HOW TO INSTALL

- How to Install Bamboo Charcoal Wood Veneer

- Should Acoustic Panels Be on Walls or Ceilings?

- Step-by-Step Guide to Installing PVC Marble Sheets

- WPC wall panel installation method

- How to install SPC wall panels?

- How to install bamboo charcoal wood veneer?

- Enhancing Sound Quality with Acoustic Panels

- How to install Bamboo Charcoal Wood Veneer?

ROOMS & SPACES

- PVC Marble Sheet Manufacturer in China for Hotel Interior Wall Projects

- Key Installation Points of WPC Wall Panel Concealed Door Systems

- Customization and Wholesale Services of PVC Marble Sheets Suitable for Star-Rated Hotel Decoration

- Interior Bedroom Design Styles: Enhancing Aesthetics with Modern Wall Panels

- Can I Use SPC Wall Panels in a Shower?

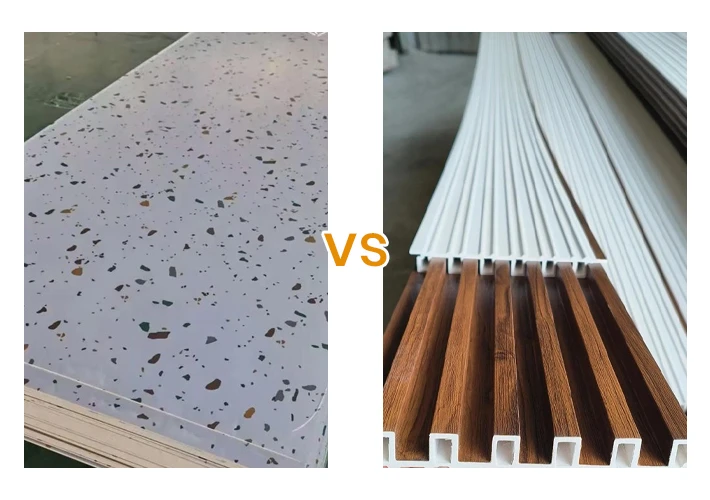

- Guide to Wall Panel Types

TOP EXPERT ADVICE

- How to Shorten Hotel Guestroom Renovation Time by 30%?

- What Real Problems Will a Project Face If CE Documentation Is Incomplete?

- Bamboo Charcoal Wood Veneer Price Guide & Global Market Trends

- Top WPC Wall Panel Manufacturer and Factory for Global Projects

- Top 10 Best Acoustic Panels for Modern Interior Decoration

- How to Choose the Best Hotel Luxury Sofa for Your Project

- Latest Market Trends of WPC Wall Panels in 2025

- Common Sizes of Acoustic Wood Paneling: A Comprehensive Guide for Global Buyers

LEARN THE BASICS

- 2026 Bamboo Charcoal Wood Veneer Price Trend

- WPC Wall Panel Price in USA – Import Cost Guide

- Advantages of Using Soundproof Doors in Hotels

- Common Sizes of Acoustic Wall Panels in Ireland

- Fire Rated PVC Marble Sheet Price and Certification Cost Impact

- What are the benefits of bamboo charcoal panels?

- How to Choose the Right Acoustic Insulation Wall Panels for Commercial Projects

- Benefits of Using Acoustic Panels on Ceiling in Hotels

POPULAR COLLECTIONS

INSPIRATION

POPULAR COLLECTIONS

INSPIRATION

POPULAR COLLECTIONS

INSPIRATION

POPULAR COLLECTIONS

INSPIRATION

INSTALLATION & ADVICE

POPULAR COLLECTIONS

INSPIRATION

INSTALLATION & ADVICE

EXPLORE US

INSTALLATION & ADVICE